Optimize the crispy texture of cereal bars with Nexweet® Allulose & Fiberest® Resistant Dextrin

2024.08.07Optimize the crispy texture of cereal bars with Nexweet® Allulose & Fiberest® Resistant Dextrin

Consumers are trying to add more fiber into their daily intake of snack bar

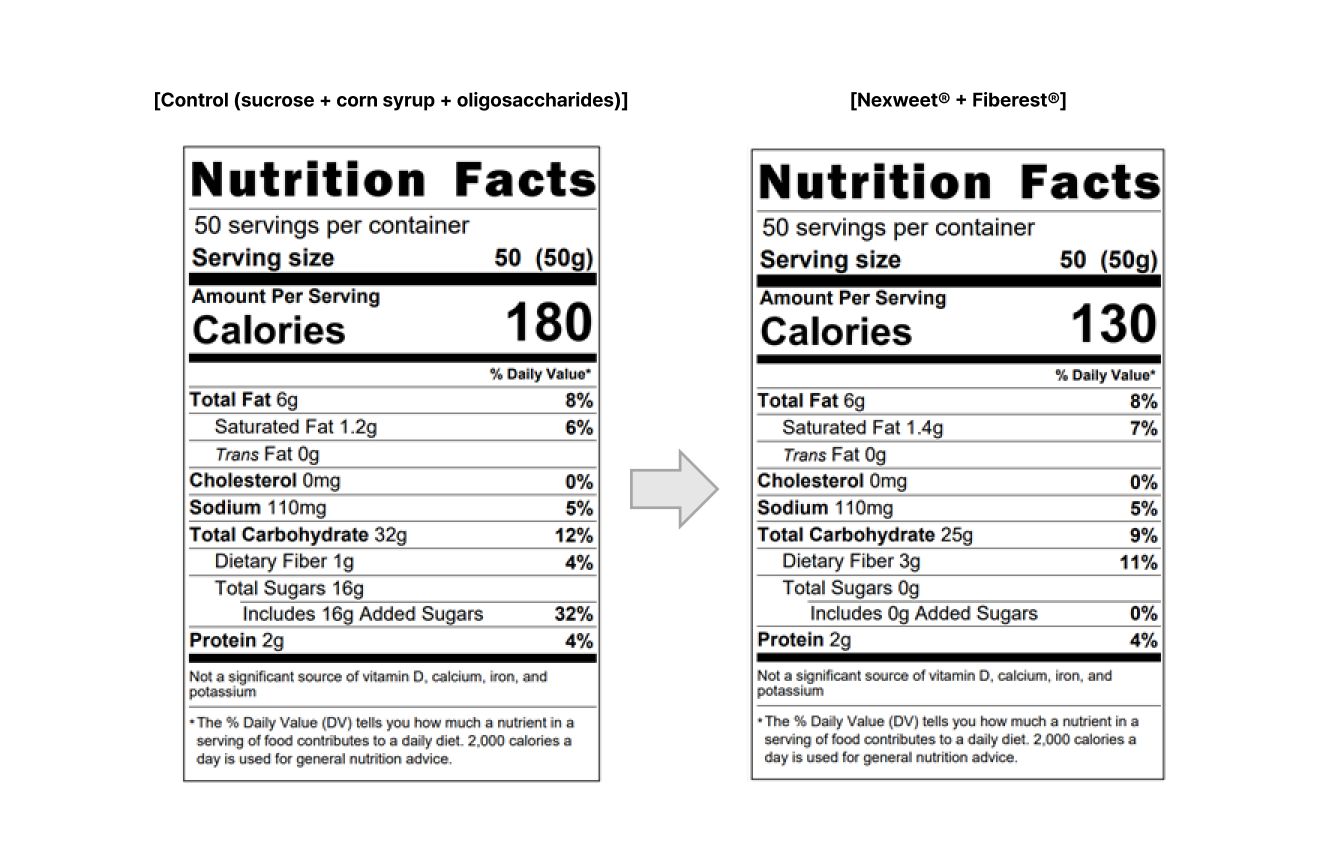

As convenient and healthy foods gain popularity among consumers, the cereal bar market is also growing. Energy claims have naturally grown as more people consume these bars as meal replacements and for post-workout energy boosts. While this is not surprising, it is noteworthy that consumer interest in gut health support has recently increased the demand in the snack bar market.1)

▲Source 1. Consumer survey result (US : motivation for trial, snack bars, 2022)

1) US: 1,000 internet users aged 18+, Kantar Profiles/Mintel, November 2022

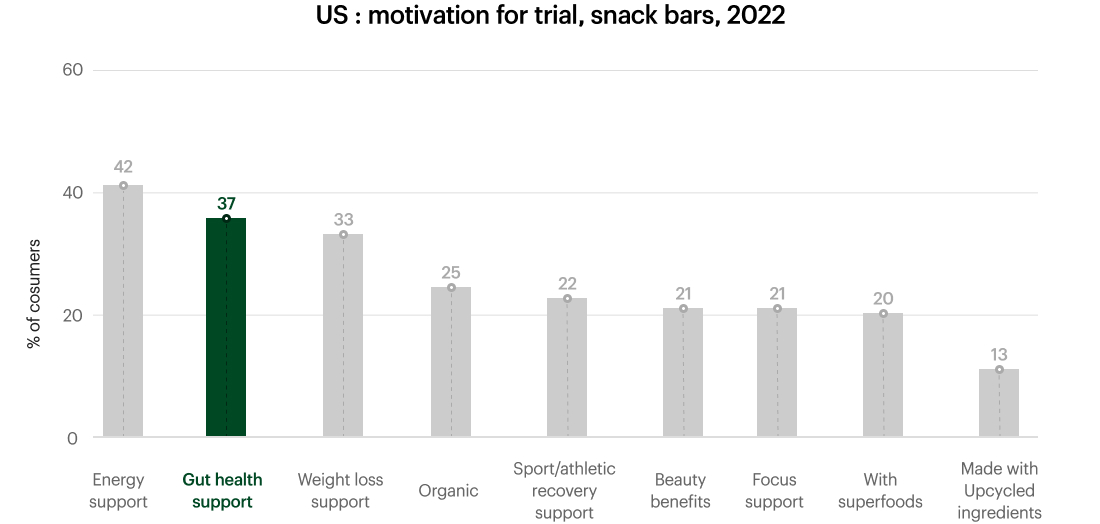

In particular, the launch of snack bars with high-fiber and wholegrain claims has been prominent in the North American market. Corresponding with consumer awareness of the link between high-fiber foods and a well-functioning gut, high-fiber claims appeared on 11% of all snack bar launches in North America in the year leading up to July 2022. The average fiber content in snack bars reached 9g per 100g in 2022. Launches with wholegrain claims saw a notable jump over the past year.2)

▲Source 2. Snack bar launches, North America, by share of wholegrain and high-fiber claims, 2018-22

2) Mintel GNPD, August 2018-July 2022

How to make cereal bar?

The main ingredients of cereal bars are sugars (such as corn syrup, sucrose, oligosaccharides), grains (such as oats, puffs, corn flakes), and nuts (such as peanuts, almonds). The general manufacturing process involves first mixing liquid ingredients like sugars and oils, heating the mixture to create a syrup with the target Brix, then preparing the dry base by mixing in grains and nuts. These two mixtures are then combined in a specific ratio. The resulting mixture is pressed by using a roller, then goes through cutting, cooling, and packaging stages to produce the cereal bars.

So, what’s the challenge?

In non-baked cereal bars, sugars provide sweetness, bind the dry base, and retain moisture, ensuring that the product remains soft over time without losing moisture. The type of sugar used in a cereal bar determines its sweetness and texture. Removing sugar from the product to meet the reduced sugar claim criteria leads to challenges in sweetness, texture, and moisture retention.

The Key is right ingredient solution!

By applying our solution that combines Nexweet® Allulose & Fiberest® Resistant Dextrin, it is possible to reduce sugar contents while also creating a desired texture in cereal bars. Additionally, this solution increases fiber contents, thereby enhancing the nutritional profile to meet consumer needs.

<Samyang’s Suggestion>

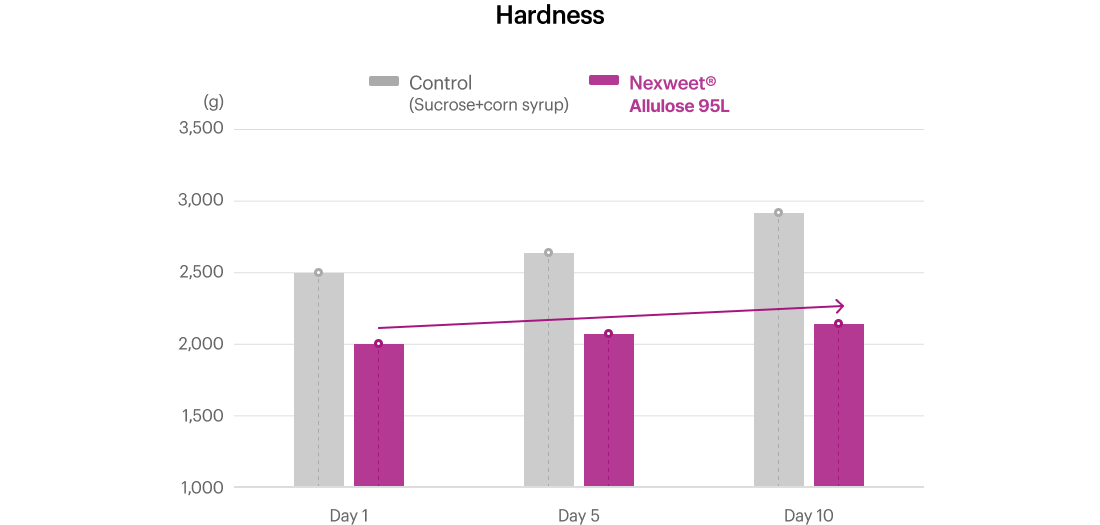

1. Nexweet® prevents cereal bars from becoming hard

The monosaccharide Nexweet® Allulose has an exposed hydroxyl group compared to disaccharides and polysaccharides, giving it a strong affinity for water. Using it can enhance the soft texture of cereal bars compared to using traditional sugars (such as sucrose, corn syrup, and oligosaccharides), and it can also reduce hardening over time. Using Nexweet® Allulose results in increased moisture content but decreased water activity, thereby enhancing microbial stability.

▲Image 1. Hardness change test of Nexweet® allulose applied bar

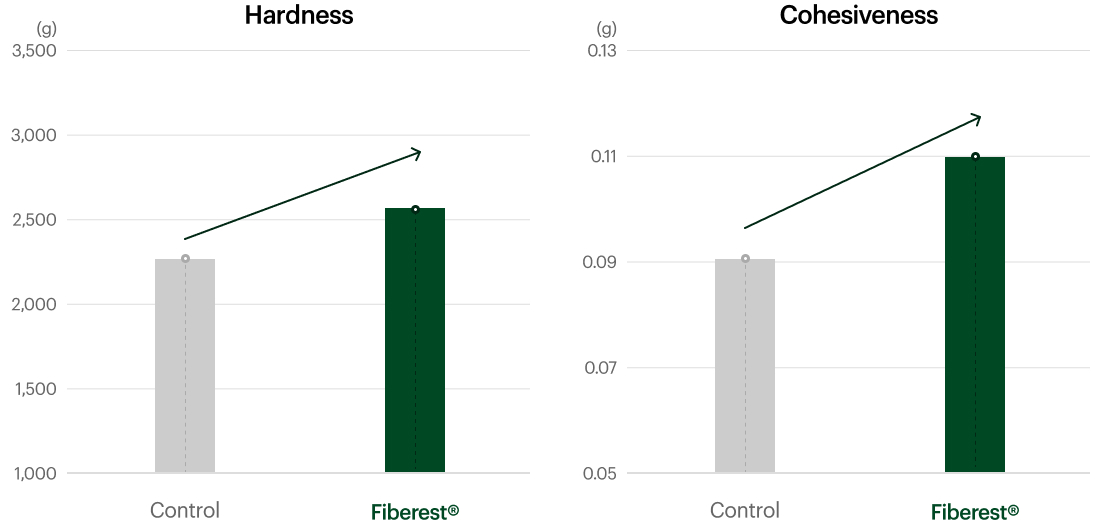

2. Fiberest® increase crispiness and binding property

Fiberest® Resistant Dextrin has a high molecular structure with low reducing sugar content, which increases the hardness of cereal bars compared to the control (sucrose+corn syrup +oligosaccharides). It enhances the crispy texture to complement the main ingredients like grains and nuts in cereal bars. Additionally, its polymeric structure increases the viscosity of the syrup and improves the binding strength between ingredients.

▲Image 2. Hardness & cohesiveness test of Fiberest® resistant dextrin applied bar

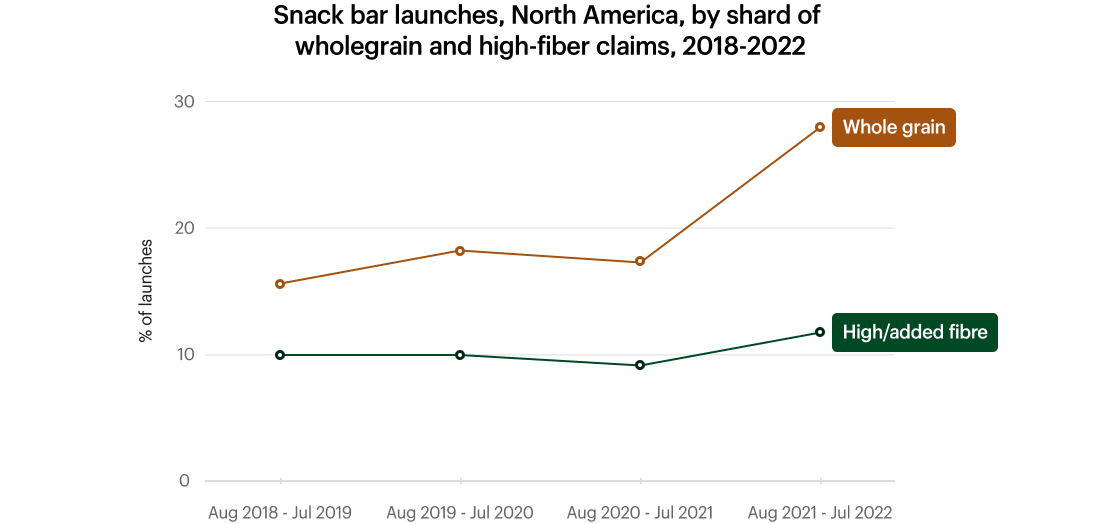

3. Zero sugar & High fiber Cereal bar made with Nexweet® & Fiberest®

using Samyang’s solution, you can create a syrup that replaces traditional sugars (sucrose+corn syrup +oligosaccharides) and produce a zero-sugar cereal bar. Nexweet® Allulose is a low-calorie ingredient with 0.4 kcal/g and is excluded from total sugar and added sugar labeling according to FDA guidelines. Additionally, unlike high-intensity sweeteners (HIS), it has bulking properties, which help compensate for the loss of body when traditional sugars are removed. Fiberest® Resistant Dextrin is a soluble dietary fiber with over 90% dietary fiber content. It can support gut health by enhancing the growth of probiotics and the amounts of positive metabolites (e.g. SCFAs).

▲Image 3. The prototype images of cereal bar

[Key ingredients]

: Allulose syrup (Nexweet® Allulose 95L), Soluble corn fiber (Fiberest® Resistant Dextrin), Steviol glycosides, Polyglycitol, maltitol. grain flakes, Cornflakes, Crispy Oatmeal, peanut, oat flakes, almonds

[Benefits]

✓ Zero Sugar (<1.0g/50g)

✓ No Added Sugar

✓ 25% Reduction in Calories

✓ Good Source of Fiber (3.0g/50g)

[Nutrition Facts]