No Added Sugar & High Fiber Gummies with Nexweet® Allulose & Fiberest® Resistant Dextrin

2024.01.18No Added Sugar & High Fiber Gummies with Nexweet® Allulose & Fiberest® Resistant dextrin

Why is it hard to realize sugar reduction in confectionery?

Sugar reduction is a substantial trend in every food and beverage category, but it is hard to realize sugar-reduced but sugar-like products in the confectionery market.

✓ Consumers of confectionery value more indulgence than health claims; thus, manufacturers do not easily sacrifice their products’ taste.

✓ Sugar itself plays a critical role not only in sweetness but also in physicochemical properties.

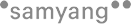

Still, there is a potential growth opportunity with gummies. According to the growth in Gummies/Jellies with new product launches by Innova Database, it showed the increasing CAGR in gummies industry. Also, they mentioned that fortified gummies with high/source of fiber claims with prebiotics ingredients (fiber such as resistant dextrin) facilitates expansion.

Source: Innova Database (What’s Trending in Gummies & Candies in US & Canada – Sep.2023)

Considerations When Manufacturing sugar reduction gummies.

Most confectionery products, including gummies, contain over 80% solid content, with more than 90% of this solid content composed of sugars (sucrose, corn syrup). Therefore, when substituting sugars with high-intensity sweeteners (HIS), the sweetness may be similar to that of sugars, but the unique taste and texture change significantly. Thus, it is essential to consider not only sweetness but also texture.

Firstly, for taste, a sweetness like sugar/corn syrup is required. Sugar alcohols or HIS were commonly used for reducing sugars, but there are still problems with the cooling effect of sugar alcohols and the bitterness or lingering aftertaste from excessive use of HIS.

Secondly, for texture, a smooth texture and chewiness are necessary to gummies. Even when the sweetness is adjusted to regular products, it is essential to find some ingredients that can complement the body texture of sugar and corn syrup.

Therefore, to successfully manufacture reduced-sugar gummies, it is crucial to choose appropriate ingredients and find the best solutions to achieve the desired products.

Samyang's Suggestion:

1. Optimal Sweetness Properties

To achieve sweetness characteristics and profiles like sugar and corn syrup, it is suggested to appropriately blend allulose (Nexweet® Crystalline Allulose) and steviol glycosides. Allulose (Nexweet® Crystalline Allulose) has a caloric value of 0.4 kcal/g and is not classified as an added sugar. The sweetness level is 70 (compared to 100 for sugar), so it is effective in manufacturing reduced-sugar gummies when it used with steviol glycosides. Typically, using HIS is common to obtain a small amount of sweetness when reducing sugar, but this can result in bitterness or lingering aftertaste. However, allulose (Nexweet® Crystalline Allulose) has the effect of boosting fruity flavors and masking the sharp, bitter taste of nutrients. So, by applying allulose and steviol glycosides to gummies, the similar sensory qualities can be achieved compared to regular products.

2. Anti-Recrystallization Effect

Erythritol, one of the 0kcal ingredients, is commonly used as a sugar substitute to reduce sugar and calories in gummies. However, gummies manufactured using sugar alcohol such as erythritol may experience recrystallization issues. Allulose (Nexweet® Crystalline Allulose), however, has the advantage of maintaining the chewy and moist characteristics of gummies by preventing crystal formation. This allows for the provision of superior products to consumers, not only with low/reduced calories but also with excellent taste and texture.

▲Image 1. Crystal formation test of Nexweet® Crystalline Allulose and Erythritol

3. Bulking Effect

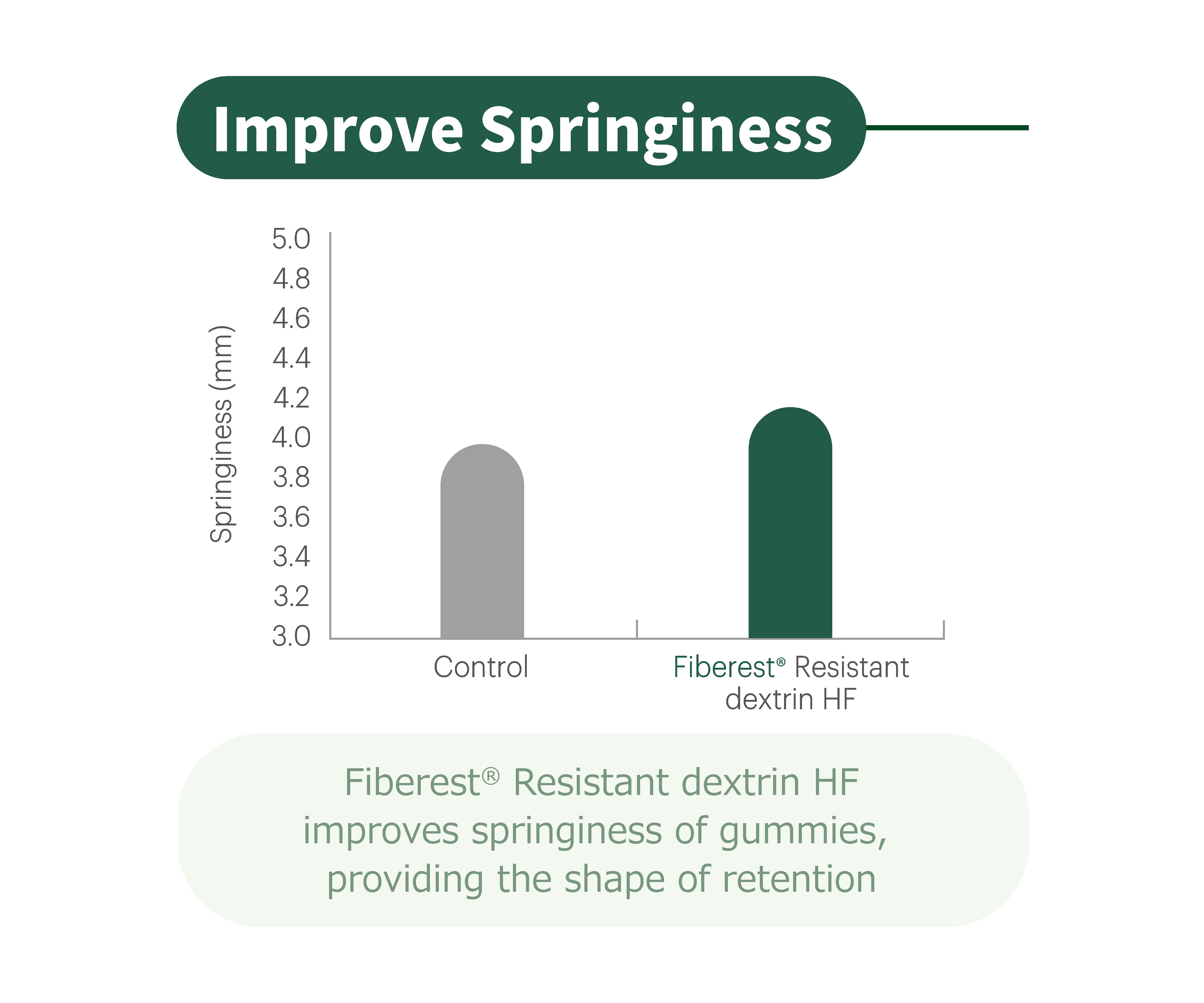

When replacing sugars in gummies with allulose (Nexweet® Crystalline Allulose) and HIS, the sweetness condition can become similar to regular products. However, there might be a bit of challenge due to the softening texture caused by the low molecular weight of allulose (Nexweet® Crystalline Allulose) compared to that of sugars. In contrast, applying resistant dextrin (Fiberest® Resistant dextrin HF) can increase springiness of gummies because of its high molecular weight, allowing for a texture that is not overly soft. Additionally, resistant dextrin (Fiberest® Resistant dextrin HF) provides the shape retention of gummies in the process of distribution. resistant dextrin (Fiberest® Resistant dextrin HF) also has characteristics with no color and odor. Therefore, using resistant dextrin (Fiberest® Resistant dextrin HF) as a bulking agent allows not to affect to the final products’ flavor, taste, and color.

▲Image 2. Springiness texture test of Fiberest® Resistant dextrin HF

[Key ingredients]

: Allulose (Nexweet® Crystalline Allulose), Soluble dietary fiber (Fiberest® Resistant dextrin HF) and steviol glycosides

[Benefits]

✓ No added sugar

✓ 60 % reduction in calories

✓ Anti-recrystallization

✓ Favorable chewy texture

✓ Clean label with high source of fiber

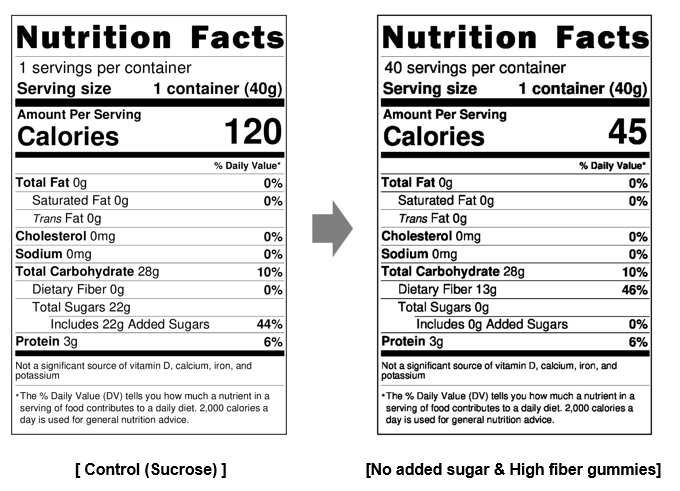

[Nutrition Facts]